Mobile Unit Snapshot: MU-B8 A 53′ Support Trailer for REMI and Engineering Teams

MU-B8 | 53-Foot Straight Support Trailer for Broadcast, REMI, and Engineering Teams

Field Production Support Trailer with 10 Workstations and Modular Cable Infrastructure

The MU-B8 is a 53-foot straight support trailer engineered for live production teams requiring dedicated technical workspace in the field. With a climate-controlled, non-expanding design and 10 operator positions, MU-B8 provides efficient and reliable infrastructure for engineering, audio, comms, and production coordination. Its internal layout is designed to accommodate multiple disciplines without overlap, making it an essential tool for REMI workflows, hybrid events, and mobile production compounds.

This mobile trailer is structured to support flypack deployment, crew overflow, signal management, and cable routing without the overhead of a full production switcher. Built for efficiency and designed to integrate seamlessly with larger production trucks, MU-B8 delivers utility and performance in a compact, high-function format.

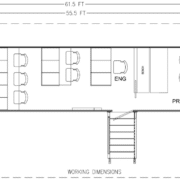

Interior Layout and Functional Zones

The MU-B8 trailer is segmented into four operational zones to enable parallel workflows. The rear storage room includes shelving and open space for flypacks, fiber drums, expendables, and engineering carts, accessible via rear entry stairs. Adjacent to the storage room is the audio room, an acoustically treated workspace for A2 support, comms coordination, or clean feed monitoring. At the center of the trailer is the engineering bay, which provides three workstations for patching, system control, and network management. The front of the trailer contains the production area, equipped with four operator desks ideal for producers, show callers, or control staff. This layout ensures separation between departments while maintaining connectivity across disciplines.

Power and Climate Support

MU-B8 operates on single-phase 208-volt power at 150 amps and connects via Camlock input to generator or shore power sources. Rear-mounted HVAC units provide stable climate control across all internal zones. This power and environmental configuration allows MU-B8 to maintain optimal conditions for both personnel and rack-mounted gear during extended deployments.

Cable Infrastructure and Customization

The MU-B8 trailer is built with modular cable capacity. Cable sets are pre-configured per event and may include Triax, DT12 audio multicore, SMPTE hybrid fiber, TAC-12 tactical fiber, XLR audio, and coaxial looms in both 5-wire and 10-wire configurations. This makes MU-B8 highly adaptable to a wide range of production formats and integration scenarios. It can be configured as a patch bay, cable landing zone, fiber terminus, or system prep room depending on show requirements.

Use Cases and Deployment Scenarios

MU-B8 is frequently deployed in support of REMI productions, flypack staging, and overflow crew operations during large-scale live events. It serves as a central hub for engineering, audio support, and production coordination. Ideal use cases include sports broadcasting, touring concerts, government events, town halls, music festivals, hybrid corporate shows, and distributed control workflows. Its compact footprint enables quick deployment and efficient use of compound space, especially in environments where primary expando trucks are already at capacity.

Why MU-B8 Stands Out in the Field

What sets MU-B8 apart is its focused design as a dedicated support unit. Unlike full production trucks, it does not include a switcher, router, or replay systems, which frees up interior space for teams that handle infrastructure, logistics, and support systems. It is commonly paired with production units like MU-10, MU-14, or MU-28 to offload comms, fiber management, and auxiliary control functions. The clear departmental separation and operator comfort make MU-B8 an essential tool for any production that requires reliable support in the field.

Specifications Summary

Trailer Length: 53 feet

Working Area: 61.5 feet long by 18 feet wide

Structure Type: Straight, non-expando

Operator Positions: 10

Power: 208 Volts, Single Phase, 150 Amps

Cooling: Rear-mounted A/C units

Cable Types: Triax, DT12, SMPTE, TAC-12, XLR, 5-wire and 10-wire coax

Integration: Camlock connectors for generator or shore power

Gross Vehicle Weight: Not specified (standard class for 53-foot support units)

Contact for Booking or Custom Configuration

To schedule MU-B8 for your next broadcast or production event, or to request custom cable loads and workstation configurations, contact Live Media Group directly:

Phone: 833.933.54483

Email: solutions@livemediagroup.com

Please reference MU-B8 when inquiring.